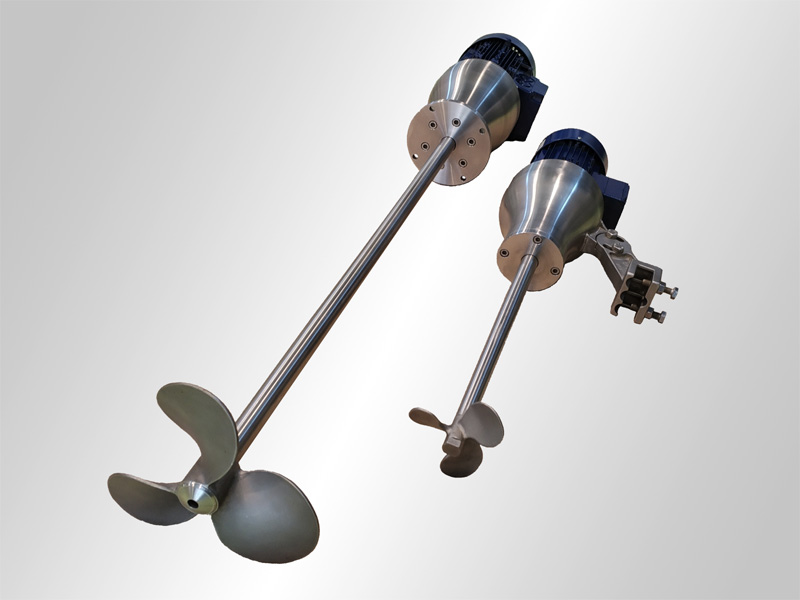

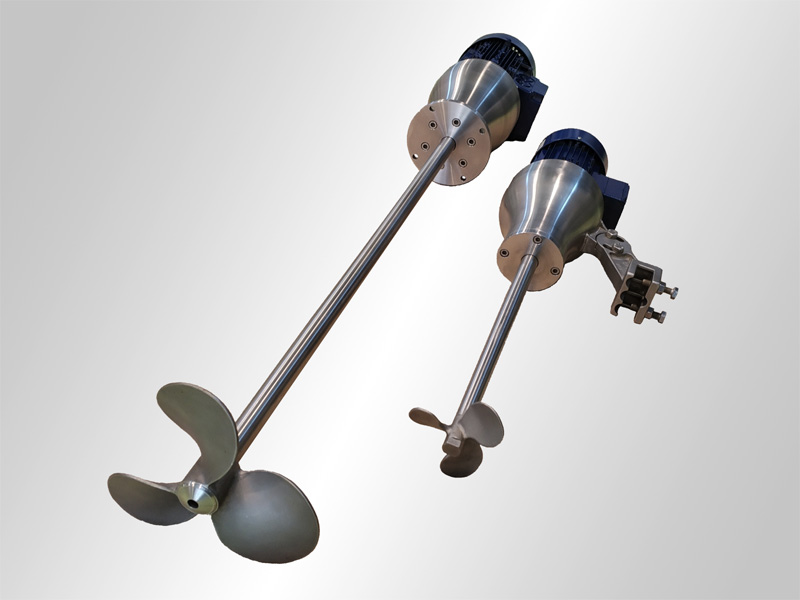

Our immersion mixers are made entirely of 304/316 stainless steel and rapresent an ideal solution both for chemical and food sector. The careful technical construction and the use of only quality components determine its strenght and durability over time. Each mixer is scrupulously tested and balanced in order to reduce vibrations and noise to minimum.

Versatile and customizable: available in bracked or flanged version (also on Customer's drawing), they are easily adaptable to any type of tank and plant. The wide choice of engines, propellers and shafts makes them adaptable to liquids of different viscosities and alo allows a wide range of customizations to satisfy even the most demanding Customers.

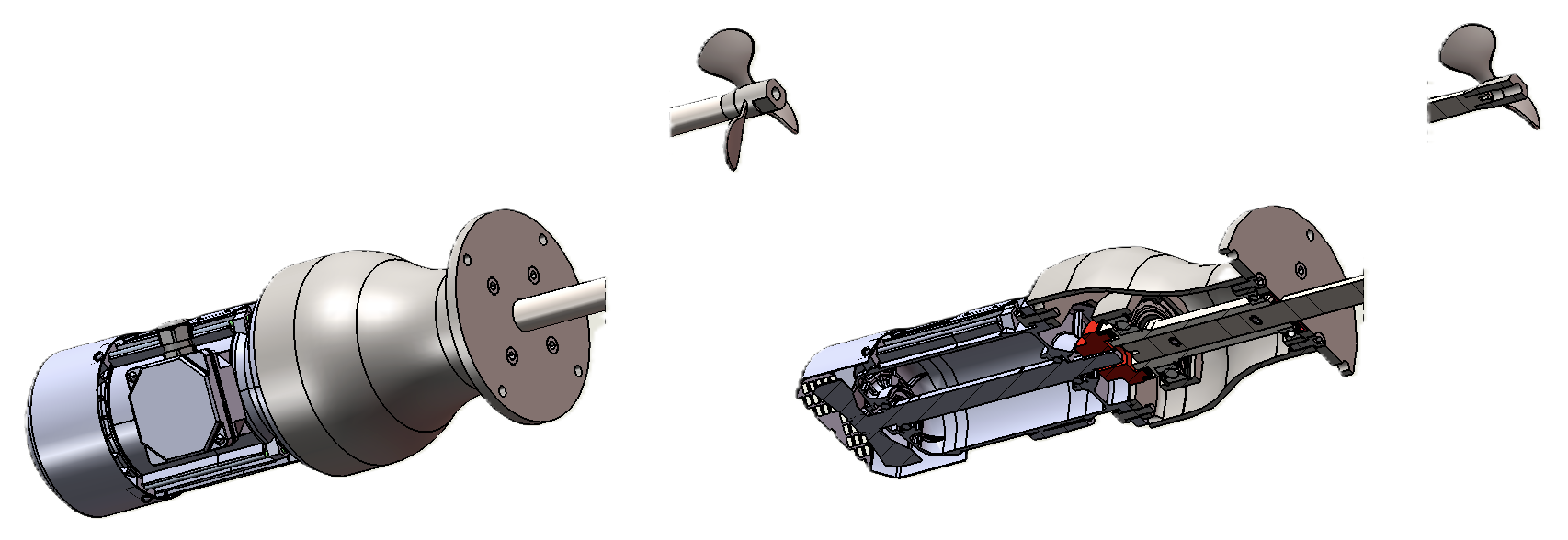

AGP / AGQ - Premium Immersion Mixers

"For the most demanding Customers..." our premium series mixers combine uncompromising elegance and ruggedness. On requirement AGP mixers can be combined with moto-reducer or motoinverter to adjust rotation speed

CHARACTERISTICS

As default they come with a precision-cast impeller in AISI 316, balanced and electropolished, available in diameters 90, 120, 160 or 220 mm;

According to viscosity different type of impellers are also available;

AISI 304 body, fully machined, with rugged and captivating design PAM 71-132;

h7 ground AISI 316 shaft available in diameters 25/30 mm, length 400-1200 mm;

IP55 single-phase/three-phase motor, powered by 220/380 V - 50 Hz, available in 2, 4, 6, 8 poles and with power from 0.25 up to 3 Hp;

(Optional) Motoinverter or Motoreducer for rotation speed adjustment without loss of torque, controllable via display or remotely;

Internal components including joint, bearings and seals made in Italy;

Easy to install and maintain

0512 53580250